About Us

Luoyang Sunrui Titanium Precision Casting Co., Ltd

Luoyang Sunrui Titanium Precision Casting Co., Ltd. was originally Titanium R&D Department of No.725 Research Institute (Luoyang Ship Material Research Institute) which is a branch of World Top 500 Enterprises nominated “China State Shipbuilding Corporation (CSSC)”.

Company Founded in

Patents Owned

Main/Participating National Standards

Annual Production Capacity

Product Center

Specializing in the research, development, production, and service of high-end titanium alloy materials and their products

Titanium Alloy Precision Castings

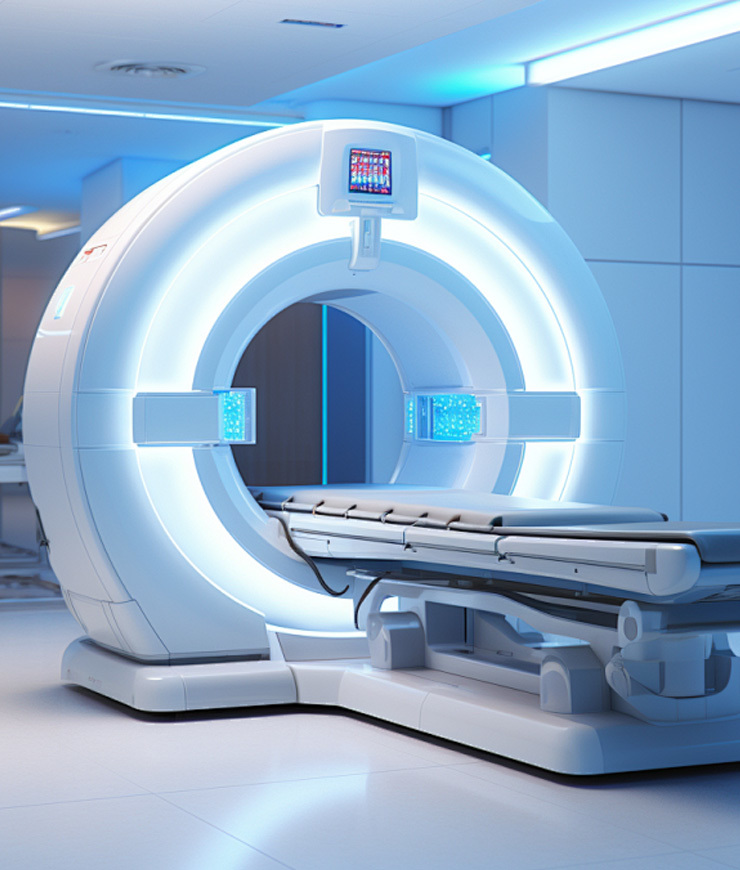

The medical casting products of titanium alloy and cobalt chromium molybdenum alloy have formed large-scale production, and currently have the ability to produce 3 million precision castings annually. The service field has also expanded to aerospace, shipbuilding, sports, medical equipment and other fields.

Learn More →The company has the production capacity to produce 5000 tons of titanium and titanium alloy castings, plates, strips, rods, titanium welded pipes, titanium heat exchangers, intelligent heat exchange units, and special alloy castings annually.

Learn More →Titanium and Titanium Alloy Plates & Strips

The company has a complete titanium plate and strip production line, mainly including melting production lines (large direct air consumable arc furnace, electron beam cold bed melting furnace, CNC milling machine, sawing machine, etc.), hot rolling production lines (reversible hot rolling machine, push steel heating furnace, movable roller bottom furnace, eleven roll straightening machine, etc.), cold rolling production lines (reversible cold rolling machine, degreasing unit, finishing unit, well vacuum annealing furnace, large plate vacuum annealing furnace, sandblasting unit, pickling unit, etc.), high-precision roller grinding machines, etc.

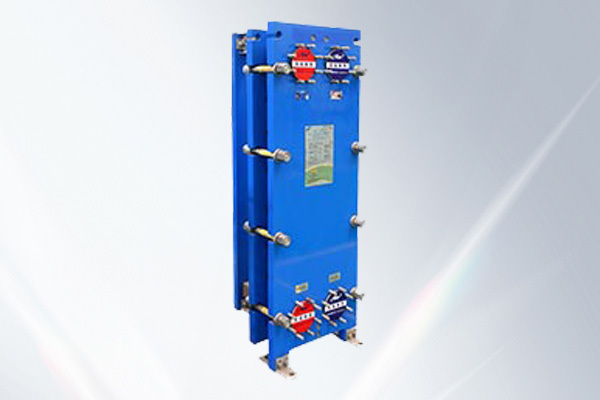

Learn More →The company has several world-class hydraulic presses and CNC shearing machines, and can currently produce various types of plate heat exchangers ranging from DN25 to DN400. The plate heat exchangers produced by the company are widely used in the fields of ships, chemicals, electricity, seawater desalination, and HVAC.

Learn More →Application Areas

The high-quality titanium and titanium alloy products produced are widely used in shipbuilding, marine engineering, aerospace, seawater desalination, power and nuclear power, petrochemicals, medical, and new energy development.

Energy and Chemical Engineering

Years of experience in the R&D of marine titanium castings. Due to the excellent high corrosion resistance of graphite mold castings to seawater, they are widely used in the shipbuilding and marine industries. The graphite mold castings produced have covered 90% of the Chinese market for marine titanium castings.

Years of experience in the research and development of aerospace titanium investment castings. Currently, titanium investment castings have been successfully supplied to major aircraft manufacturers at home and abroad.

In the sporting goods field, titanium alloys are used to manufacture bicycles and golf clubs. Titanium alloy frames are strong, lightweight, and have good shock absorption, improving riding comfort and speed; while titanium alloy club heads can increase hitting power and accuracy, improving athletic performance.

With advancements in technology and cost control, titanium alloys are starting to enter the realm of everyday consumer products, such as high-end watch cases, eyeglass frames, and phone and computer casings, leveraging their corrosion resistance, resistance to deformation, and unique visual appeal.

In the medical field, titanium alloys are used to manufacture implantable devices such as artificial joints, bone plates, and intramedullary nails. This is due to their good biocompatibility, non-toxicity, reduced rejection reactions, and facilitation of human recovery. In addition, titanium alloys are also used in oral restoration, such as dental implants and denture frameworks, exhibiting good biostability and mechanical properties.

Blog

Specializing in the research, development, production, and service of high-end titanium alloy materials and their products

Quality Certification

View More →Production Workshop

View More →